Making sure your company's Supplier Code of Conduct Policy is applied in China is not something to be taken for granted. Scandic Sourcing has provided Supplier Code of Conduct audits in China since 2008. We provide a customized programs aligned with updated requirement on ESG and GRI sustainability reporting. With a team on the ground in China with solid experience in the manufacturing industry we have the experience to asssit our clients to put together an effective supplier code of conduct audit program.

Riding Style

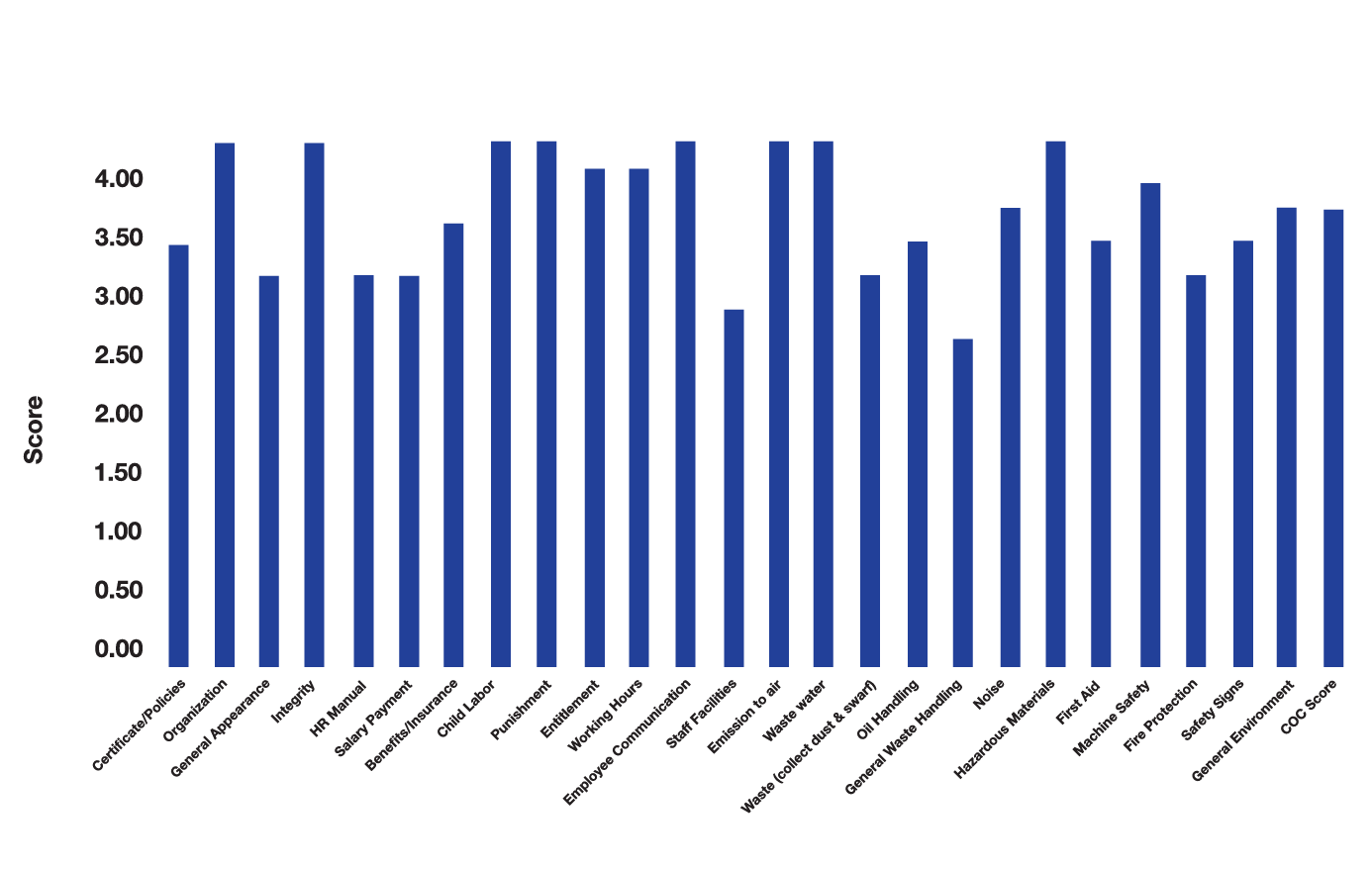

Each issue is graded on a four-point scale , measured and visualized. This make s it possible both to track issues and improvements of individual suppliers, as well as the status of the complete supplier pool. Above an example of an audit for a machining company.

Code of Conduct Program Contents

Every industry and every company has different risk and issues. Scandic Sourcing’s Code of Conduct program covers your selection of GSE, EHS issues including governance, labor, environment and factory safety. It is also possible to add quality systems and customer specific issues to the program

Program Development

Scandic Sourcing will engage client organisations stakeholders and together identify areas of materiality, set priorities and requirments. In this way we develope a customized Supplier Code of Conduct-program that reflects your internal values, international standards, local laws and regulations as well as the state of the industry, where tangible and realistic goals will be set for your China suppliers. The program will be design so that key areas are prioritized and audit can be done in limited time. An important part is also training of the purchasing and supply chain team so they feel part of the process.

Program Management

Scandic Sourcing will provide periodic reports over a specificed time-frame about the state of your suppliers and the Code Of Conduct work. The service includes maintaining collected data, planning and preparing audits, making annual or quarterly reports, and access to our database with real-time data about your supplier pool.

Code of Conduct Audit

Scandic Sourcing’s engineers and specialists will visit your supplier’s plants and conduct field audits. After the audit, the team reviews and discuss each valuation point in the report preparation to ensure fairness and consistency and provide a detailed report to our client including a punch list for the supplier to follow up on.

Feedback

The Scandic Supplier Code of Conduct Program is a contiuous improvement program. Through regular audits of the supplier pool individual and systematic weaknesses can be accessed. New targets can be set and decision of supplier improvment or pruning programs made. The information and data points develop also fits right into your annual sustainability report.

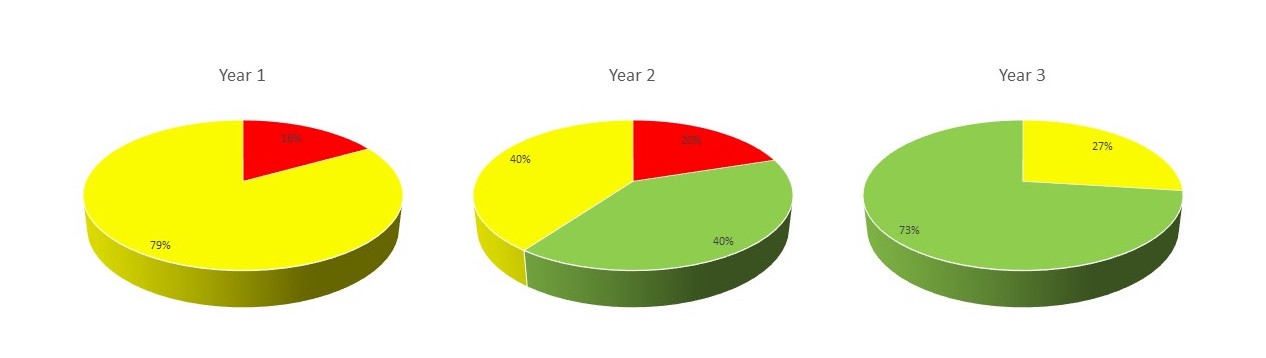

An example of a gradual Code Of Conduct-program implemented over a three year period. The test scores translates into the colors red (need urgent actions), yellow (need improvements), green (acceptable).

Impact

Scandic Sourcing received the 2012 Swedish Chamber of commerce Innovation price for its Supplier Code of conduct program. The award was presented by Swedish Minister of Trade Dr. Eva Björling at a Cermony at Qinghua University in connection with a state visit.

Impact

Scandic Sourcing received the 2012 Swedish Chamber of commerce Innovation price for its Supplier Code of conduct program. The award was presented by Swedish Minister of Trade Dr. Eva Björling at a Cermony at Qinghua University in connection with a state visit.

Case Study: Delaval

DeLaval is a major supplier to the Dairy Industry with manufacturing operations in the USA, Europe and Asia. Scandic Sourcing performed Code Of Conduct audits for 50 suppliers to Delaval over a five year audit, and brought a majority of them up to the green classification standard set by Delaval and Scandic Sourcing. The Code of Conduct Audit had many benefits for the overall reliability of Delaval's supplier base in China. Delaval Case Study.